Wood Plastic Composite (WPC) wall panels have come a long way since their introduction, thanks to continuous technological advancements and innovations in the industry.

These advancements have resulted in significant improvements in the quality, durability, and versatility of WPC wall panels.

In this essay, we will explore the evolution of WPC wall panels, highlighting the key technological advances and innovations that have shaped their development.

We will discuss the advancements in material composition, manufacturing processes, surface finishes, and installation methods.

I. Enhanced Material Composition: Achieving Optimal Performance

A. Improved Wood and Plastic Blend Early iterations of WPC wall panels often faced challenges related to material strength, stability, and durability.

Technological advancements have led to the development of improved wood and plastic blends, incorporating additives and reinforcements to enhance the overall performance of the panels.

These new formulations ensure better resistance to moisture, UV radiation, impact, and temperature fluctuations.

B. Sustainable Material Options In recent years, the industry has witnessed a shift towards more sustainable material options for WPC wall panels.

Manufacturers are incorporating recycled and renewable materials, such as reclaimed wood fibers and bio-based polymers, reducing the reliance on virgin resources and promoting eco-friendly practices.

II. Advanced Manufacturing Processes: Ensuring Consistency and Quality

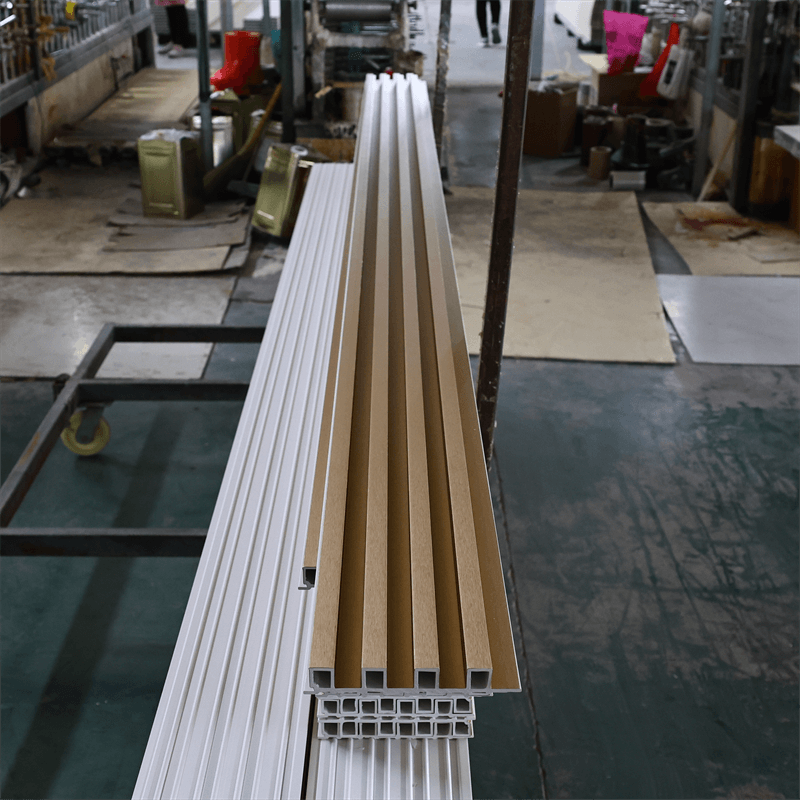

A. Extrusion Techniques Extrusion is a key manufacturing process for WPC wall panels.

Technological advancements in extrusion techniques have led to more precise control over the panel’s dimensions, surface texture, and overall quality.

Improved extrusion machinery, advanced cooling systems, and automated control systems have contributed to consistent and high-quality panel production.

B. Co-extrusion Technology Co-extrusion technology has revolutionized the manufacturing of WPC wall panels.

This process involves the simultaneous extrusion of multiple layers with different properties, resulting in panels with enhanced performance characteristics.

For example, a co-extruded panel may feature a durable outer layer for weather resistance, a core layer for structural strength, and an inner layer for moisture protection.

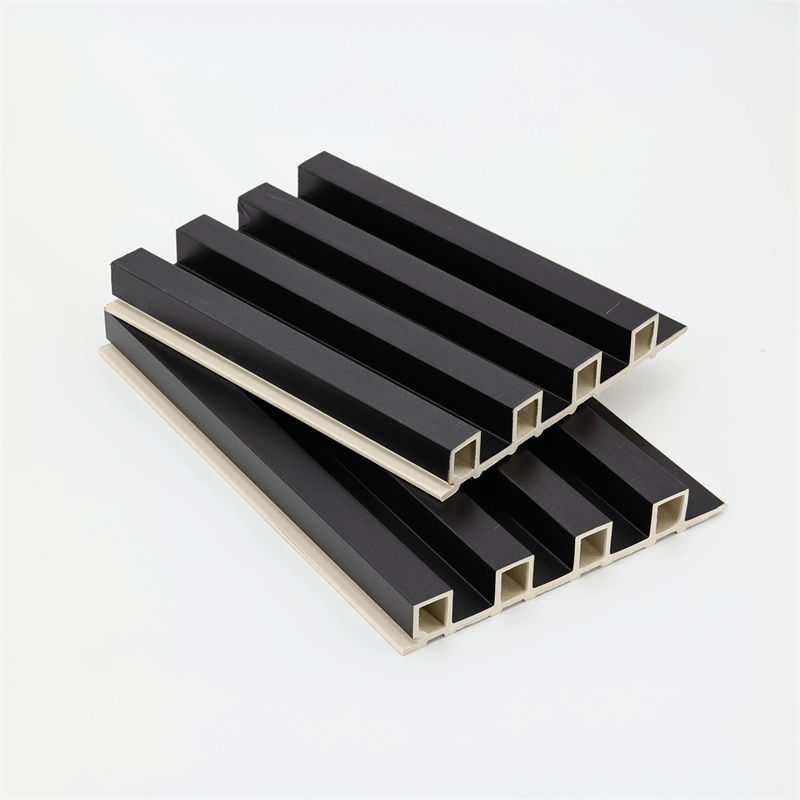

III. Surface Finishes: Aesthetics and Longevity

A. Enhanced Texturing and Embossing Advancements in surface finishing techniques have allowed manufacturers to create WPC wall panels with realistic wood grain textures, embossed patterns, and unique designs. These surface finishes enhance the visual appeal of the panels, mimicking the natural beauty of wood while providing improved resistance to scratches, stains, and fading.

B. Protective Coatings and Finishes To enhance the durability and longevity of WPC wall panels, manufacturers have introduced advanced protective coatings and finishes.

These coatings provide additional resistance against UV radiation, moisture penetration, and impact, ensuring that the panels retain their original appearance and performance over an extended period.

IV. Innovative Installation Methods: Ease and Efficiency

A. Click-and-Lock Systems Traditional installation methods for WPC wall panels involved screws or adhesives, which could be time-consuming and labor-intensive.

However, technological advancements have introduced click-and-lock systems, simplifying the installation process.

These systems allow for easy and efficient panel installation, reducing the need for specialized tools or professional assistance.

B. Hidden Fasteners Innovative hidden fastener systems have also emerged, offering a seamless and visually appealing installation for WPC wall panels.

These systems eliminate the need for visible screws or nails, providing a clean and uniform surface.

Hidden fasteners not only enhance the aesthetic appeal but also improve the overall structural integrity of the installed panels.

The evolution of WPC wall panels has been driven by continuous technological advancements and innovations in material composition, manufacturing processes, surface finishes, and installation methods.

These advancements have resulted in the development of WPC panels with enhanced performance, improved aesthetics, and easier installation.

As the industry continues to innovate, we can expect further improvements in the quality, durability, and sustainability of WPC wall panels,

making them an even more desirable choice for a wide range of architectural and design applications.

In conclusion, the evolution of WPC wall panels has transformed the industry, offering a technologically advanced and versatile solution for architectural cladding.

Through advancements in material composition, manufacturing processes, surface finishes, and installation methods, WPC wall panels have become a superior alternative to traditional wall materials.

The improved material composition ensures optimal performance, with enhanced strength, stability, and durability.

Sustainable material options contribute to eco-friendly practices and reduce the reliance on virgin resources.

Advanced manufacturing processes result in consistent and high-quality panels, while co-extrusion technology enables the creation of panels with enhanced performance characteristics.

The introduction of innovative surface finishes, such as realistic wood grain textures and protective coatings, enhances the visual appeal and longevity of WPC wall panels.

Furthermore, innovative installation methods like click-and-lock systems and hidden fasteners simplify the installation process, providing ease and efficiency.

With their blend of functionality, aesthetics, and sustainability, WPC wall panels are revolutionizing the architectural cladding industry.

As technological advancements continue, we can expect further improvements in WPC wall panels, offering even more innovative features and benefits.

Whether it’s for residential, commercial, or industrial projects, WPC wall panels provide a modern, durable, and environmentally friendly solution.

Embracing the evolution of WPC wall panels opens up a world of design possibilities, transforming spaces with their beauty, performance, and ease of installation.